Citing his statement, he said that during a visit to Vietnam, Jensen Huang, co-founder and chief executive officer of Nvidia Corp, affirmed that Vietnam is the only country that can fully participate in all stages of the semiconductor chain.

Vietnam has great potential for semiconductor growth

Recently, NVIDIA Corporation signed an important agreement worth US$200 million with FPT Corporation and is continuing to actively seek business cooperation and investment opportunities in Vietnam.

Not only NVIDIA Group but also more than 50 semiconductor industry enterprises such as Intel, Amkor, Hana Micron (packaging, testing), Ampere, Marvell, Cadence, Renesas, Synopsys, Qorvo (design), Lam Research, Coherent (equipment manufacturing) are currently operating in Vietnam. Among them, there are projects worth hundreds of millions of dollars, even billions of dollars such as projects of Intel, Amkor, and Hana Micron.

In addition, a number of domestic companies have also engaged in the semiconductor industry market such as Viettel, FPT, and VNChip. Therefore, economic experts predict that by 2024, Vietnam's semiconductor industry will reach a value of about US$6.2 billion.

Over the past 30 years, the value chain of the global semiconductor industry has taken shape. To produce a chip, from design to packaging to market, it takes 4-6 months with over 500 stages, traveling more than 55,000km in about 70 countries. This also means that it is not at all easy for developing countries to join in the chain.

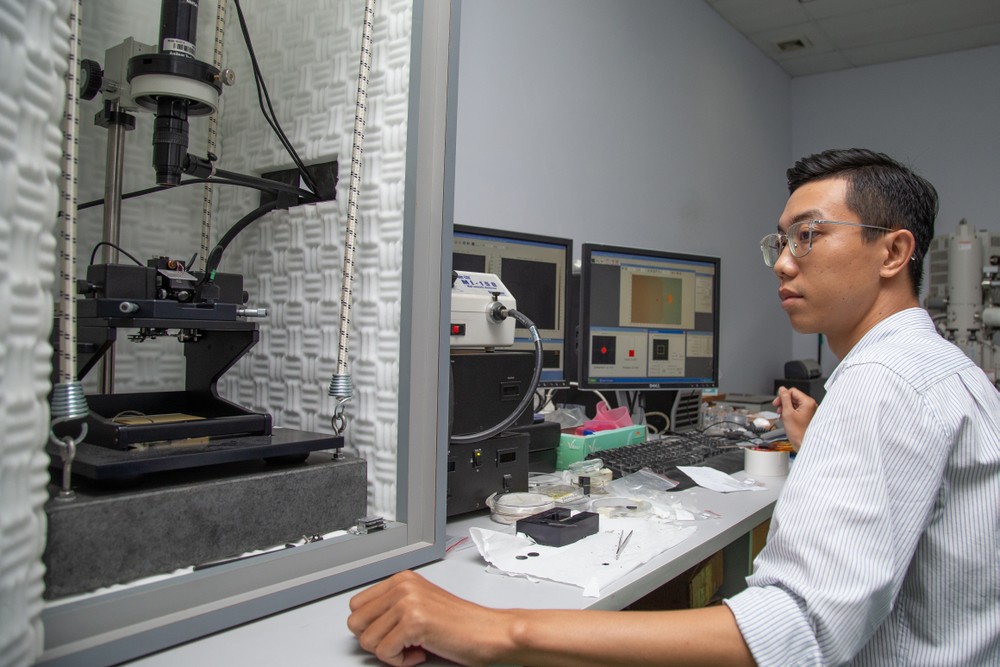

Particularly, Vietnam – a country lagging so far behind other countries has very good human resource potential according to technology corporations as a large proportion of Vietnamese technology engineers have been working in the US, Korea, Singapore, and Taiwan ( China). Economic analysts say that Vietnamese people are talented in math, engineering, technology and science (STEM), which are basic elements in semiconductor technology.

Focus on human resource training

According to data from the US Semiconductor Industry Association, by 2030, there will be a need for about 1 million more IC semiconductor engineers globally. In Vietnam, from now until 2030, Minister of Planning and Investment Nguyen Chi Dung said that at least 50,000 engineers are needed which means the country needs a number of engineers 10 times the number of existing engineers, including at least 5,000 people with knowledge in artificial intelligence (AI).

Currently, the application of AI to develop the semiconductor industry and the development of the semiconductor industry to serve AI development is increasingly popular and is an irreversible general trend, with the participation of large corporations such as NVIDIA, Google, Meta, Apple, Microsoft, said Minister Nguyen Chi Dung.

Agreeing with this opinion, Deputy Director Nguyen Cuong Hoang of Viettel High-Tech Industry Corporation said that Viettel needs about 500 semiconductor design engineers by 2030 and more than 1,000 engineers by 2035.

At a conference on human resource development for the semiconductor industry held at the end of April, Prime Minister Pham Minh Chinh said that human resource training for the semiconductor industry is ‘a breakthrough of breakthroughs’. The Government has assigned the Ministry of Planning and Investment to draft a project to develop human resources in the semiconductor industry. This draft proposes to establish four national shared semiconductor centers including two in Hanoi, one in Da Nang, and one in Ho Chi Minh City.

Additionally, 18-20 standard training centers at universities will be invested by the state budget.

The US partner has committed to sponsoring two laboratories specializing in measurement and testing located at the National Innovation Center (NIC) Hanoi and Ho Chi Minh City National University.

The estimated cost for human resource training is about VND26,000 billion, equivalent to more than $1 billion. However, people were wondering whether graduates of training centers can meet the needs of businesses.

Prof. Tran Xuan Tu, Director of the Institute of Information Technology of Hanoi National University, admitted that in the semiconductor industry, chip designing brings the highest profit, accounting for about 52 percent-55 percent of a product’s cost, followed by manufacturing-related stages, about 24 percent-25 percent and the rest is for packaging and testing. Currently, businesses in Vietnam focus a lot on packaging and testing. In the long term, the country needs to train more human resources who will engage in the design stage - the stage that brings the highest value.

Director Phung Viet Thang of Intel in Vietnam also said that in the semiconductor industry, there are many different stages. Each stage has different human resource requirements. Therefore, it is necessary not only to have a general strategy but also to have a separate action program for each human resource that needs to be developed depending on Vietnam's strengths in each specific period.

Currently, Vietnam ranks ninth globally in the field of electronics exports and is considered to have a fast-growing semiconductor ecosystem with the potential to improve its position in the global semiconductor supply chain. Intel Corporation's packaging and testing factory in Ho Chi Minh City has shipped more than 3 billion chips by the end of 2022 and has plans to expand investment in the Southeast Asian country.

Vietnamese enterprises such as Viettel and FPT also began to participate in the global chip supply chain. To realize the goal of affirming a strong position in the global semiconductor industry chain, Vietnam is making efforts to perfect specific mechanisms and policies to ensure competition with countries in the region while synchronously developing infrastructure of electricity, water, transportation, fiber optic cable, information technology and training high-quality human resources.

Jetking Global Group CEO Harsh Bharwani affirmed that in the next 10 years, Vietnam will become a leading country in the semiconductor chip industry.