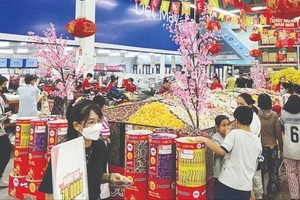

Enterprises struggle to maintain production amid the complicated developments of the Covid-19 pandemic. (Photo: SGGP)

Enterprises struggle to maintain production amid the complicated developments of the Covid-19 pandemic. (Photo: SGGP)

Maintaining production or suspending operations to wait for the pandemic to end?

That is the biggest concern of many business owners in the context that the Covid-19 pandemic has spread in many provinces and cities, including Ho Chi Minh City, especially small and medium-sized enterprises. Because of their small capital and weak internal resources, they cannot afford to pay the costs to prevent the pandemic and maintain production.

Mr. Tran Quoc Trong, CEO of Thanh Long Wine Company in Long An Province, said that the company had to suspend operations from July this year because it did not have enough funds to support workers to stay at the factory and carry out Covid-19 tests for workers. He said that his company must wait until the Covid-19 pandemic is under control to resume operations.

Similarly, Mr. Le Vuong Quoc, Deputy Director of Gimex Vietnam Joint Stock Company, said that in Can Tho and Tien Giang, many agricultural product processing enterprises - partners of the company - had completely ceased production activities to fight against the pandemic. The stages of preliminary processing and packaging of agricultural products, especially agricultural products for the export market, need to use a large number of workers, so it is difficult to both organize production and fight the pandemic because the costs are too large. Moreover, currently, import-export enterprises are facing many difficulties, such as a shortage of workers and drivers, and container backlog. In addition, container shipping rates have highly increased, seriously affecting import and export activities.

Increasing shipping rates along with many other costs incurred for pandemic control have become great pressure on enterprises. For instance, at Cat Lai Port, because transshipment is overloaded, when exporting goods, many enterprises have to bring their goods to the port a few days earlier to wait. Meanwhile, the costs of demurrage and cold storage are extremely expensive, about US$80 per day. On the other hand, for the food, foodstuff, and agricultural products industry, the longer the demurrage time, the higher risk that exported goods are being returned because the quality of goods is affected. This situation has put many enterprises at risk of shutting down because the more they produce, the more they suffer losses, especially for enterprises with many workers.

Regarding this issue, Ms. Le Bich Loan, Deputy Head of the Management Board of the Saigon High-tech Park (SHTP), added that the SHTP had been carrying out measures quite effectively to prevent the pandemic. However, enterprises can only implement three-on-site production in a short time. If it takes a long time, it is hard for enterprises to maintain production. Currently, on average, each enterprise in the industrial park has to spend several billion Vietnamese dongs per month on accommodations and Covid-19 tests. Therefore, enterprises only maintain a limited number of workers to fulfill export orders with scheduled delivery time. Many enterprises said they would not receive new orders if they have to prolong the three-on-site production model.

Flexible solutions

Ms. Le Bich Loan said that it is necessary to reduce unnecessarily incurred costs to remove difficulties for businesses amid the current context. Accordingly, it is essential to recalculate the regulation on the frequency of Covid-19 testing. Because with the average number of workers from a few hundred to several thousand people of each enterprise, the cost of testing is about several billion Vietnamese dongs per week. Besides, it is necessary to carry out Covid-19 vaccination for enterprises. The solution to do this is to socialize the supply of vaccines. It must be determined that vaccines are not too special goods to need strict control, as currently, or only allow a few enterprises to buy and import.

The Hepza Business Association proposes to convert the three-on-site solution into two-on-site and one-green-zone, in which workers produce and eat at the factory, but they can sleep in a green zone - the safe area. Workers in the green zones are tested by enterprises twice in five days. In addition, authorities should administer Covid-19 vaccines to workers in export processing zones and industrial parks. In particular, Covid-19 vaccination should be prioritized for workers in the export and manufacturing industries of electronic products, textiles, footwear, automobiles, steel, agricultural product processing, and food processing.

Ms. Le Bich Loan informed that up to now, 63 out of 85 enterprises in the SHTP had been maintaining stable production, and no Covid-19 clusters had broken out in enterprises yet. SHTP Management Board has coordinated with enterprises to deploy various solutions to prevent the pandemic, such as maintaining the frequency of rapid tests every three days and PCR tests every seven days. In case a Covid-19 case is detected, it will be removed quickly from the production workshop. The management board has been collaborating with enterprises to build a GPS to monitor the travel route from the factory to the green zone of workers to tighten the quarantine. This is also a feasible solution that helps businesses have more workers to participate in production in the near future.

That is the biggest concern of many business owners in the context that the Covid-19 pandemic has spread in many provinces and cities, including Ho Chi Minh City, especially small and medium-sized enterprises. Because of their small capital and weak internal resources, they cannot afford to pay the costs to prevent the pandemic and maintain production.

Mr. Tran Quoc Trong, CEO of Thanh Long Wine Company in Long An Province, said that the company had to suspend operations from July this year because it did not have enough funds to support workers to stay at the factory and carry out Covid-19 tests for workers. He said that his company must wait until the Covid-19 pandemic is under control to resume operations.

Similarly, Mr. Le Vuong Quoc, Deputy Director of Gimex Vietnam Joint Stock Company, said that in Can Tho and Tien Giang, many agricultural product processing enterprises - partners of the company - had completely ceased production activities to fight against the pandemic. The stages of preliminary processing and packaging of agricultural products, especially agricultural products for the export market, need to use a large number of workers, so it is difficult to both organize production and fight the pandemic because the costs are too large. Moreover, currently, import-export enterprises are facing many difficulties, such as a shortage of workers and drivers, and container backlog. In addition, container shipping rates have highly increased, seriously affecting import and export activities.

Increasing shipping rates along with many other costs incurred for pandemic control have become great pressure on enterprises. For instance, at Cat Lai Port, because transshipment is overloaded, when exporting goods, many enterprises have to bring their goods to the port a few days earlier to wait. Meanwhile, the costs of demurrage and cold storage are extremely expensive, about US$80 per day. On the other hand, for the food, foodstuff, and agricultural products industry, the longer the demurrage time, the higher risk that exported goods are being returned because the quality of goods is affected. This situation has put many enterprises at risk of shutting down because the more they produce, the more they suffer losses, especially for enterprises with many workers.

Regarding this issue, Ms. Le Bich Loan, Deputy Head of the Management Board of the Saigon High-tech Park (SHTP), added that the SHTP had been carrying out measures quite effectively to prevent the pandemic. However, enterprises can only implement three-on-site production in a short time. If it takes a long time, it is hard for enterprises to maintain production. Currently, on average, each enterprise in the industrial park has to spend several billion Vietnamese dongs per month on accommodations and Covid-19 tests. Therefore, enterprises only maintain a limited number of workers to fulfill export orders with scheduled delivery time. Many enterprises said they would not receive new orders if they have to prolong the three-on-site production model.

Flexible solutions

Ms. Le Bich Loan said that it is necessary to reduce unnecessarily incurred costs to remove difficulties for businesses amid the current context. Accordingly, it is essential to recalculate the regulation on the frequency of Covid-19 testing. Because with the average number of workers from a few hundred to several thousand people of each enterprise, the cost of testing is about several billion Vietnamese dongs per week. Besides, it is necessary to carry out Covid-19 vaccination for enterprises. The solution to do this is to socialize the supply of vaccines. It must be determined that vaccines are not too special goods to need strict control, as currently, or only allow a few enterprises to buy and import.

The Hepza Business Association proposes to convert the three-on-site solution into two-on-site and one-green-zone, in which workers produce and eat at the factory, but they can sleep in a green zone - the safe area. Workers in the green zones are tested by enterprises twice in five days. In addition, authorities should administer Covid-19 vaccines to workers in export processing zones and industrial parks. In particular, Covid-19 vaccination should be prioritized for workers in the export and manufacturing industries of electronic products, textiles, footwear, automobiles, steel, agricultural product processing, and food processing.

Ms. Le Bich Loan informed that up to now, 63 out of 85 enterprises in the SHTP had been maintaining stable production, and no Covid-19 clusters had broken out in enterprises yet. SHTP Management Board has coordinated with enterprises to deploy various solutions to prevent the pandemic, such as maintaining the frequency of rapid tests every three days and PCR tests every seven days. In case a Covid-19 case is detected, it will be removed quickly from the production workshop. The management board has been collaborating with enterprises to build a GPS to monitor the travel route from the factory to the green zone of workers to tighten the quarantine. This is also a feasible solution that helps businesses have more workers to participate in production in the near future.

The SHTP Management Board has received many official letters from the parent companies of enterprises in the SHTP. These companies proposed the relevant authorities, especially the Ministry of Health, to allow them to deliver Covid-19 vaccines to their member enterprises and branches in Vietnam. They will bear all the costs for buying, transporting, and transferring vaccines to quickly vaccinate workers at factories, speeding up the process of herd immunity to maintain stable production.