Of the total foreign investment capital into Vietnam in the first nine months of this year, the processing and manufacturing industry saw the highest newly-licensed projects, with the registered capital of $4.7 billion, accounting for 45.5 percent of the total newly-registered capital. The supply of electricity, gas, hot water, steam, and air conditioning followed with nearly $4.4 billion, accounting for 41.9 percent. The remaining industries got $1.3 billion, accounting for 12.6 percent.

Figures by the General Statistics Office of Vietnam also show that if including the adjusted capital of licensed projects in previous years, foreign direct investment in the processing and manufacturing industry accounts for 54 percent of the total newly-registered and additional capital, reaching nearly $8.4 billion. The supply of electricity, gas, hot water, steam, and air conditioning reached $4.2 billion, accounting for 27.3 percent. The remaining industries reached $2.9 billion, accounting for 18.7 percent.

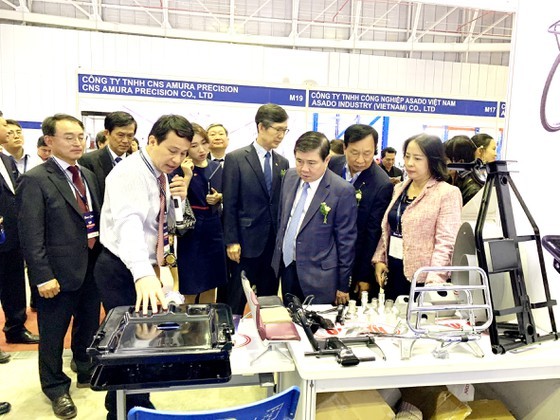

Ms. Le Bich Loan, Deputy Head of the Saigon Hi-Tech Park, said that the above facts showed that there was a strong shift in the global supply chain of supporting industry products to Vietnam. At a recent conference to connect the supply of supporting industry products, held by the People's Committee of Ho Chi Minh City, 14 international end-product manufacturers presented the list of more than 450 products, components, and supporting industry devices that need to find suppliers. Among these manufacturers, there are global brands, such as Panasonic, Samsung, and TTI.

According to Ms. Loan, the rapidly-increasing movement of FDI end-product manufacturers to Vietnam since the beginning of this year has accelerated the global supply chain of supporting industry products, in general, to Vietnam. Besides, domestic supporting industry product manufacturers have just supplied simple products. Core products with high added-value have not yet been available. And this is the potential market room for corporations specializing in the supply of core supporting industry products in particular and the manufacturing and processing industry to move to Vietnam to fill the vacancy.

On the contrary, many domestic enterprises have concerned that they would not be able to withstand the competitive pressure when the flow of foreign investment is massively pouring into Vietnam. Mr. Tong Duy Khanh, General Director of Duy Khanh Mechanical Co., Ltd., said that foreign-owned enterprises have internal financial advantages. Also, they have participated in the global supply chain for a long time, so the quality, the prices of products or experience in management, and production technology all are much more competitive than domestic enterprises.

Another issue is that there is an inequality in preferential policies between domestic and foreign enterprises. For instance, foreign enterprises importing technology and production lines enjoy the tax rate of zero percent, whereas domestic enterprises importing raw materials to produce technology and machinery have to pay an import tariff of 10 percent. Thus, from the starting point, domestic enterprises do not have the opportunity to develop the processing and manufacturing industry because they cannot compete in the cost price with imported technology and production lines. As for supporting industry products, competitiveness is even weaker.

Domestic enterprises not only have to find ways to compete with foreign enterprises, but they also encounter administrative barriers from domestic authorities. Some enterprises only applied for investment licenses to expand or build new factories to manufacture supporting industry products, but their applications have not been approved after three years. Or, as in many export processing zones and industrial zones, although the enterprise has paid 50 percent of the rent, it has not been granted a certificate of land use right. Because infrastructure investors of the export processing and industrial zones have been slow to pay the full 50-year land-use rental to local authorities. In consequence, enterprises face difficulties because they cannot borrow capital to invest and expand production scale.

Mr. Le Hoai Quoc, Chairman of the Ho Chi Minh City Automation Association, emphasized that another difficulty that domestic enterprises are coping with is the rapid development of science and technology in the world. As a result, the replacement of production lines and production technology is also very fast in the end-product manufacturing groups. It requires enterprises in general to have large enough capital to invest and quickly change production technology in line with the development trend. However, because of the weak internal financial capacity, along with the sluggish and spreading financial support from the authorities and provinces, it is extremely difficult for domestic enterprises to make breakthroughs in investment and development.