|

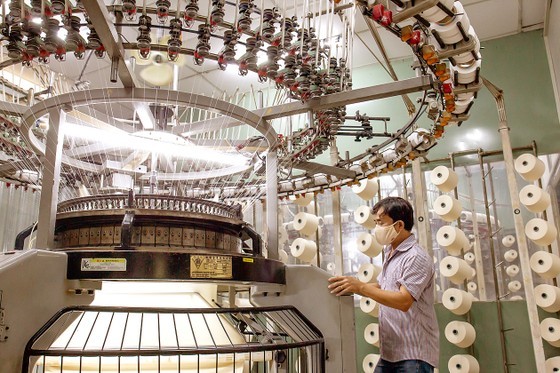

Nguyen Dung Textile Company in District 12, Ho Chi Minh City, utilizes antimicrobial fabric weaving technology to ensure product quality. |

There are currently 25,000 businesses operating in the supporting industry production sector nationwide. More than 96 percent of these businesses are categorized as small and medium-sized enterprises, and their limited collaborative capacity has been a hindrance to their participation in global supply chains.

High volume of orders

Analyzing the broader landscape of Vietnam's supporting industry, Mr. Do Thang Hai, Deputy Minister of the Ministry of Industry and Trade, stated that the market demand within the supporting industry sector holds significant potential, with an anticipated value of approximately US$300 billion by 2030. Vietnamese companies have actively participated in supplying components to prominent corporations such as Honda, Toyota THACO, Samsung, Panasonic, and Sanyo, spanning various sectors, including automotive, motorbikes, and electronics.

Furthermore, over the past time, with the growing supply capacity in the Vietnamese market, many global supply chains have been actively seeking sources for industrial support product supplies.

In agreement with this perspective, Ms. Truong Chi Binh, Vice Chairwoman of the Vietnam Association for Supporting Industries (VASI), highlighted that VASI alone encompasses 300 member businesses with small and medium-scale production capabilities actively engaging in direct and indirect exports to global supply chains. These businesses have notably expanded their presence in key markets, such as the US, Europe, Northern Europe, Japan, and South Korea.

In the current year, businesses have expanded their operations into two new markets, Africa and the United Arab Emirates (UAE). Advantageous products that Vietnamese supporting industry enterprises can produce include industrial components for the automotive sector, industrial machinery, technological equipment, electronics, and various components made from materials like aluminum, copper, and plastic, automation, single products, and high-quality molds. Components that require multi-step processing are also the strength of Vietnam.

Mr. Do Phuoc Tong, Chairman of the HCMC Association of Mechanical-Electrical Enterprises, shared some intriguing insights. In early September, member businesses of this association had the chance to connect with Boeing Corporation when its representatives visited Vietnam to seek to purchase supporting industry products. Notably, Boeing's requirements were innovative compared to the conventional products manufactured by domestic companies. Mr. Do Phuoc Tong commented, "This presents a substantial opportunity, albeit a substantial challenge, as the supporting industry enters the global arena."

The need for market guidance

Regarding the potential of the supporting industry, Ms. Truong Chi Binh outlined that, for example, in the US market, in states like Michigan, Illinois, and Texas, there is a significant concentration of mechanical businesses across various sectors, such as the automotive industry, aerospace, industrial machinery, technological equipment, and electronics.

|

Minh Nguyen Company workers at the Saigon Hi-Tech Park inspect product details. |

This presents an abundant pool of potential orders for the supporting industry to provide the appropriate components, but local businesses have not fully capitalized on this opportunity. Likewise, although the current order volume remains relatively stable in the Japanese and South Korean markets, there is a shift in the trend towards complex products and higher-value orders that Vietnamese businesses have not yet accommodated.

To promptly assist businesses in overcoming the above challenges, Mr. Nguyen Chi Sang, Vice Chairman of the Vietnam Mechanical Association, believes that manufacturing enterprises should be proactive in seeking and approaching customer partners. In addition, they must invest their focus on traditional and strategic products rather than diversifying production across various product types.

Businesses also require collaboration to establish a shared ecosystem for producing product clusters or complex products, enhancing their chances of deeper integration into the global supply chain. Simultaneously, government agencies must address exchange rates and offer favorable interest rates for loans to aid businesses in early technology upgrades for production, enabling them to meet the demands of their import partners.

Regarding market exploration, obviously, commercial counselors play a vital role in surveying and collecting information about product demand. According to recommendations from some businesses, commercial counselors should proactively update information regarding technical barriers and market-specific payment methods to mitigate the risk of businesses being misled or experiencing export returns.

Mr. Maxime Dourdan, Supply Chain Business Manager of Boeing for the Southeast Asia, Japan, and South Korea region, emphasizes that suppliers must possess automation capabilities to meet the standards demanded by Boeing and other end-product manufacturing companies.

There is no single solution for the development of the supply chain but a synchronized solution. To achieve this, Vietnamese businesses need to establish an ecosystem that produces complex products, taking into account the integration of electronic technology.

In that way, Vietnamese businesses can manufacture and supply directly to Boeing or other major global corporations. In order to become a crucial link in the global supply chain, businesses must have long-term planning and preparation.